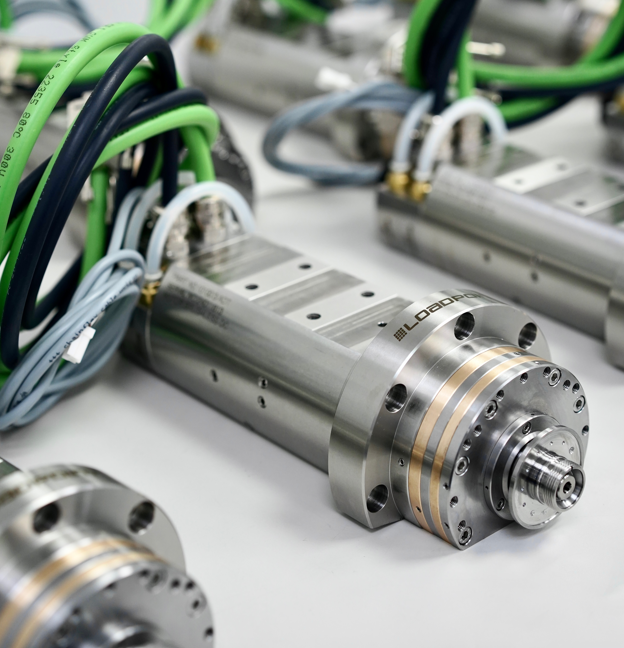

Dicing Spindles

We are the leading manufacturer of dicing spindles supplying original equipment manufacturers worldwide with products that are accepted as the industry standard.

The spindles cover a full range of blade diameters from 50 mm (2 in) up to and including 101 mm (4 in). For 50 mm diameter blades, spindles have a maximum speed of 60 000 rpm and 1.2 kW of available power. Larger spindles for 101 mm blade diameters have a maximum speed of 40 000 rpm and develop 2.5 kW of power. DC brushless motors are fitted as standard to achieve maximum operating torque over a wide range of speeds. This makes our spindles suitable for cutting a variety of materials ranging from silicon through to quartz. AC motors can also be fitted to spindles to meet customer drive specifications.

.jpg?width=2000&height=2000&name=10500-square%20(1).jpg)

Loadpoint can also fit electrical brushes for touch sensing circuits and supply balanced wheel mounts and spacers.

AC and DC drives specially matched to dicing spindle applications are available from Loadpoint. A spindle repair and retro-fitting service is also available.

11300

Upgraded version of the 10100 spindle

+ CW/CCW rotation available

+ Supports up to 3" blades

+Flexible motor type: 1.2/1.6/1.9KW

+ Optional power

+ Water cooling

11400

+Exceptionally high load capacity and rotor stiffness

+Flange and non flange available

+Supports 2" and 3" blades

+ Increased power motor: 2.2 KW

+ Water cooling

FAQs

An air-bearing dicing spindle is a high-precision motorized spindle used in the dicing process for semiconductor wafers, electronic components, and other materials. It utilizes air pressure to create a thin air film between the rotating spindle shaft and the bearing, resulting in ultra-smooth and frictionless rotation.

Unlike traditional ball bearing or hydrodynamic bearing spindles, air bearing dicing spindles do not rely on physical contact between the rotating shaft and the bearing. Instead, they utilize a thin air film to eliminate friction, vibration, and heat generation, thereby achieving higher precision, improved surface quality, and reduced wear.

Our dicing spindles offer several advantages, including higher accuracy, improved surface finish, reduced tool wear, lower maintenance requirements, and increased throughput. The frictionless rotation provided by the air-bearing technology allows for exceptionally precise and clean cuts.

Air-bearing dicing spindles can be used to dice a wide range of materials, including semiconductor wafers (such as silicon, gallium arsenide, and silicon carbide), ceramics, glass, and other brittle materials commonly found in the electronics and photonics industries.

Stainless Steel, Bronze, Aluminium, Titanium, Plastics

Yes, we have the capability to customize spindles to suit a wide range of dicing machines. These include flange mounted, gantry mounted and round bodied cantilevered spindle styles. Please feel free to contact us to discuss your requirements and explore the possibilities of customizing a spindle for your dicing machine.

Yes, we offer professional repair services for dicing spindles that experience issues or malfunctions. Our skilled technicians have extensive knowledge and experience working with various spindle models and brands. Whether it's our own spindle or a spindle from a different manufacturer, we are equipped to diagnose issues, perform necessary repairs, and restore optimal functionality.

Air spec, controller, chiller etc. - GCM