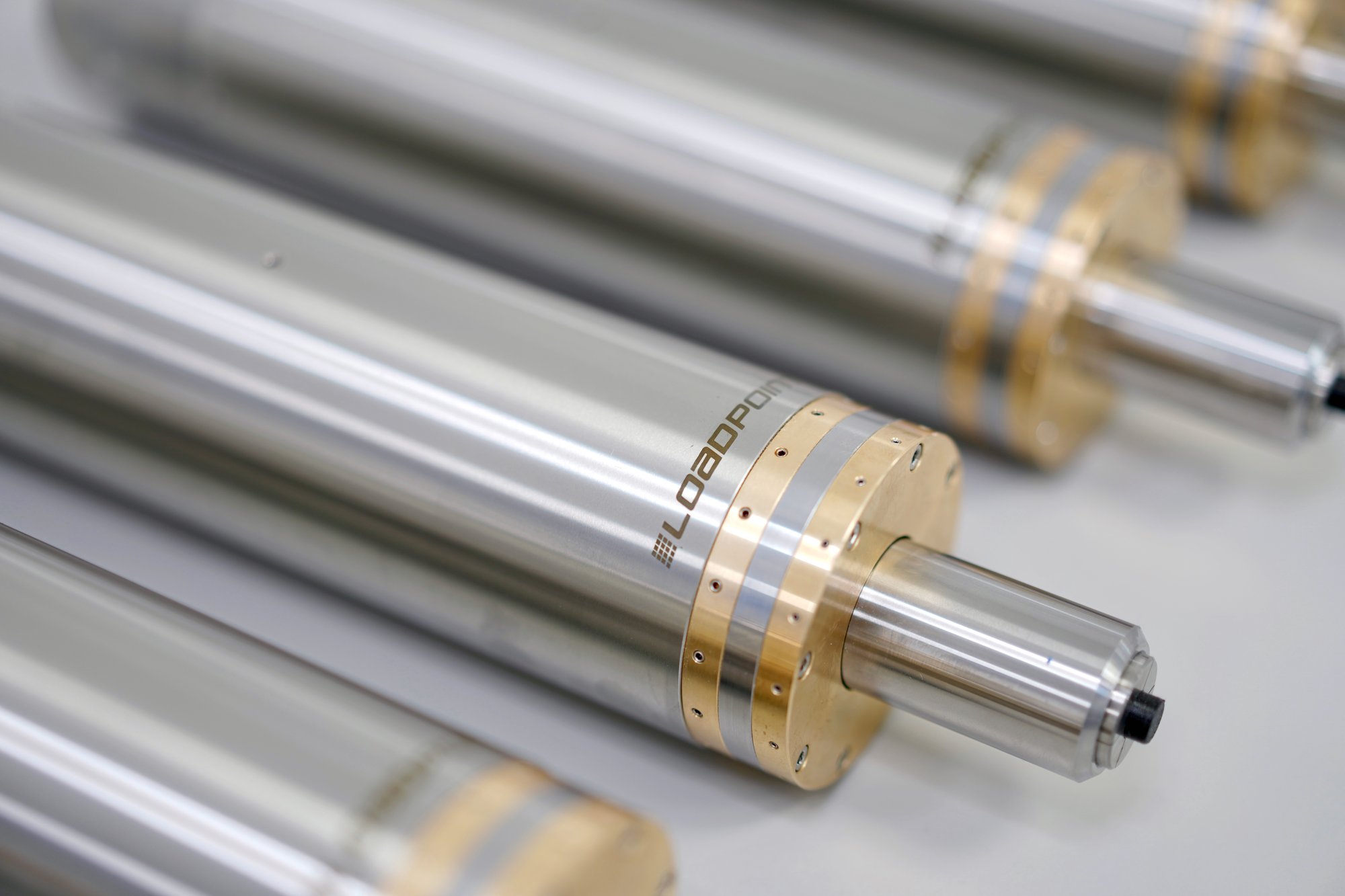

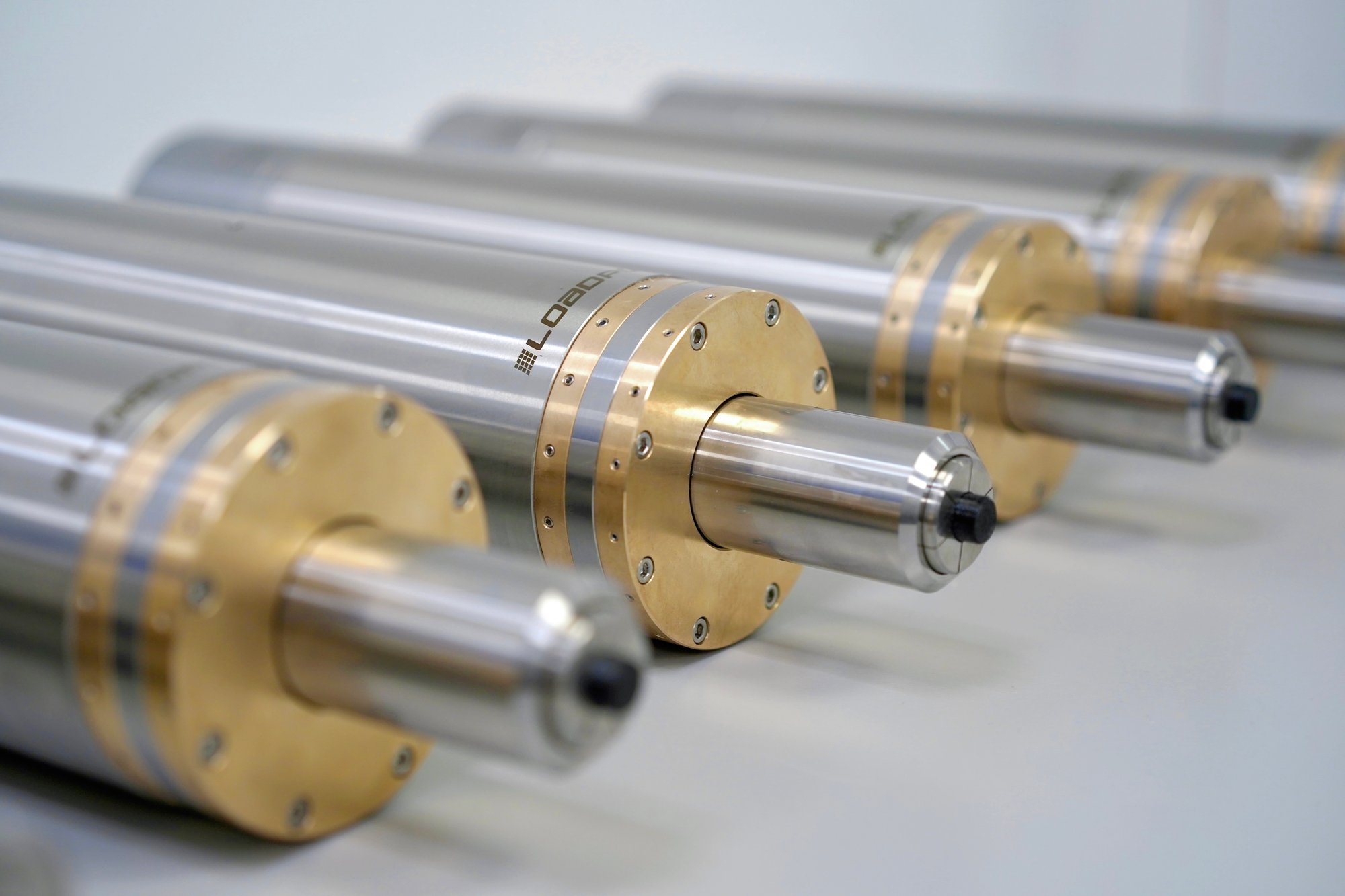

Lens Turning Spindles

Revolutionising Optical Manufacturing: Precision Lens Turning Spindle with Air Bearing Technology, a Game-Changer for Optical OEMs Specializing in IOLs, Contact Lenses, and More.

Tailored to the exacting standards of optical applications, our technology ensures that OEMs can achieve the tightest tolerances and finest surface finishes in their diamond turning operations.

Tailored to the exacting needs of IOL and contact lens OEMs, our spindles play a pivotal role in shaping lenses with the tightest tolerances and finest surface finishes. Elevate your production capabilities with our cutting-edge technology, where every rotation counts towards delivering optics that set you apart in the industry.

Partner with us for a crucial component that defines the precision in your optical manufacturing machinery.

Custom Spindles

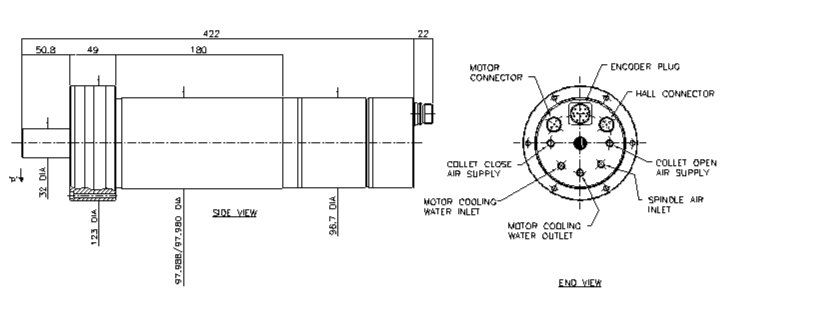

09421

+ Contact Lens Turning Spindle

+ 1000-10,000 RPM

+ Encoder Interpolation

+ ATC Collet

+ NRRO10Nm, Polish free lenses

01983

+ Contact Lens Turning Spindle

+ Maximum Speed 18,000 RPM

+ Encoder Interpolation

+ ATC Collet

+ NRRO10Nm, Polish free lenses

06526

+ Ideal Spindle for Grinding, Milling and Routing

+ Speed Max 60,000 RPM

+ CW/CCW Rotation Available

+ ATC Collet

10540

+ Contact Lens Turning Spindle

+ 1000-10,000 RPM

+ Encoder Interpolation

+ Auto Collet

+ Dynamic Runout Sub 20 NM

FAQs

A diamond turning spindle is a precision motorised spindle used in diamond turning processes to manufacture high-precision optical components, moulds, and other parts requiring extremely tight tolerances and surface finishes. It combines the capabilities of diamond cutting tools with air-bearing technology to achieve exceptional accuracy and surface quality.

Our diamond turning spindles offer several advantages, including exceptional precision, low motion error (NRRO), superior surface finish, reduced tool wear, minimised friction and heat generation, extended spindle lifespan, and enhanced stability during machining.

Diamond turning spindles can be used to machine a wide range of materials, including metals (such as aluminum, copper, and stainless steel), plastics, optical materials (like glass and crystals), and other engineering materials requiring high precision and surface quality.

Typically, smaller spindles are C. 12,000 - 15,000 rpm. Larger diamond turning spindles are 3,000-8,000 rpm.