Rotary Tables

High precision rotary tables for Wafer Inspection, Diamond Tool Machining, and Beyond

Standard height tables have the advantage of maximum axial, radial and tilt stiffness whereas reduced height tables have lower radial and tilt stiffness. All tables feature the low axial motion errors inherent of air bearings.

Optional features include large diameter central through holes for coolant feed or a central vacuum feed with rotary coupling.

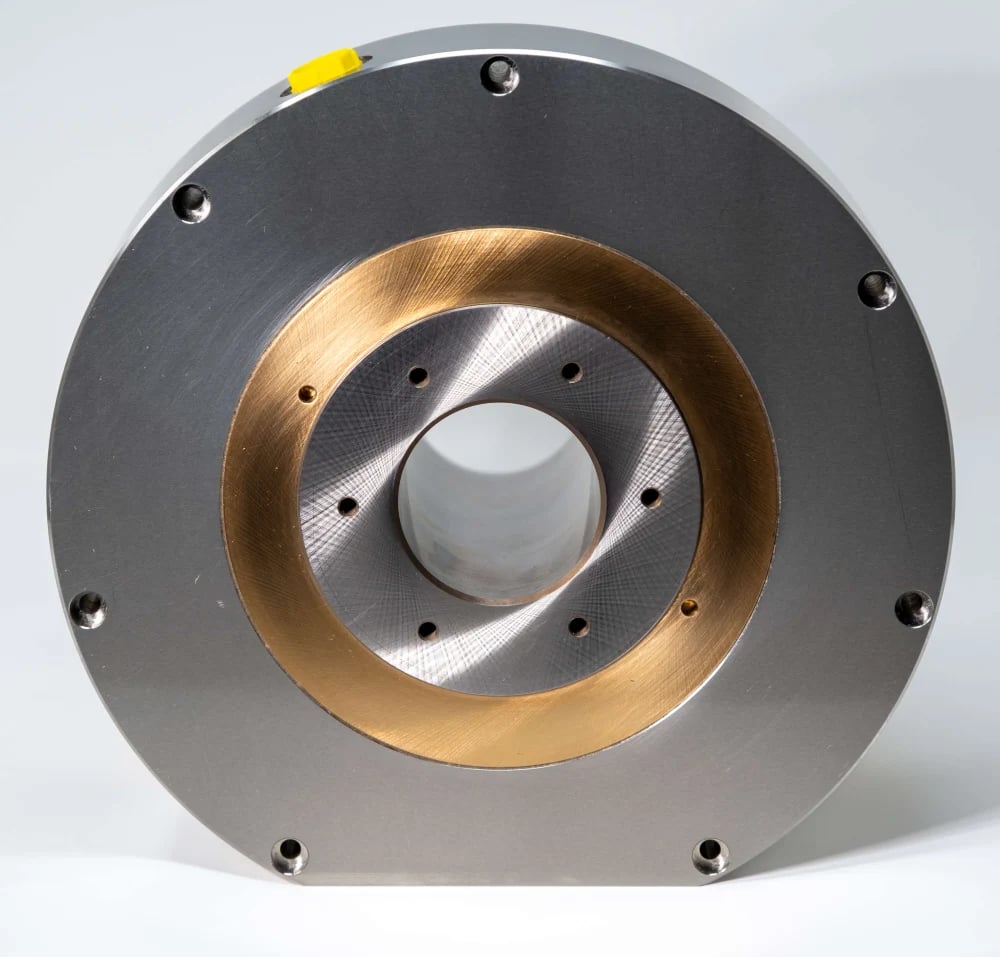

09950

+ Rotary Table for Precision Machine Tools.

+ Axial Stiffness: 180 N/um + Radial Stiffness: 9 N/um

+ Dynamic Runout sub 20nM

650301

+ Rotary Table for Wafer Inspection, Optical Metrology.

+ Dynamic Runout sub 20nM

+ Configurable Chunk Table

FAQs

Diamond tooling industry, Semiconductor wafer holding, metrology and precision grinding applications.

Air bearing rotary tables are commonly used in industries that require high positional and rotary precision and accuracy. They have exceptionally smooth rotation, enabling them to be used in applications such as the diamond tooling industry. In this industry, air bearing rotary tables play a crucial role in the manufacturing of precision diamond tools, cutting, grinding, and shaping operations.

The rotary tables can be externally driven via belts or worm and wheel, or they can be fitted with an integral drive motor and commutated with a high precision encoder.

Loadpoint offers a wide range of rotary tables, starting from 50 mm (2 in) diameter up to and including 400 mm (16 in) diameter.

The load capacity of air bearing rotary tables varies depending on the specific model and size. They are designed to handle both light and heavy loads, depending on the application requirements.