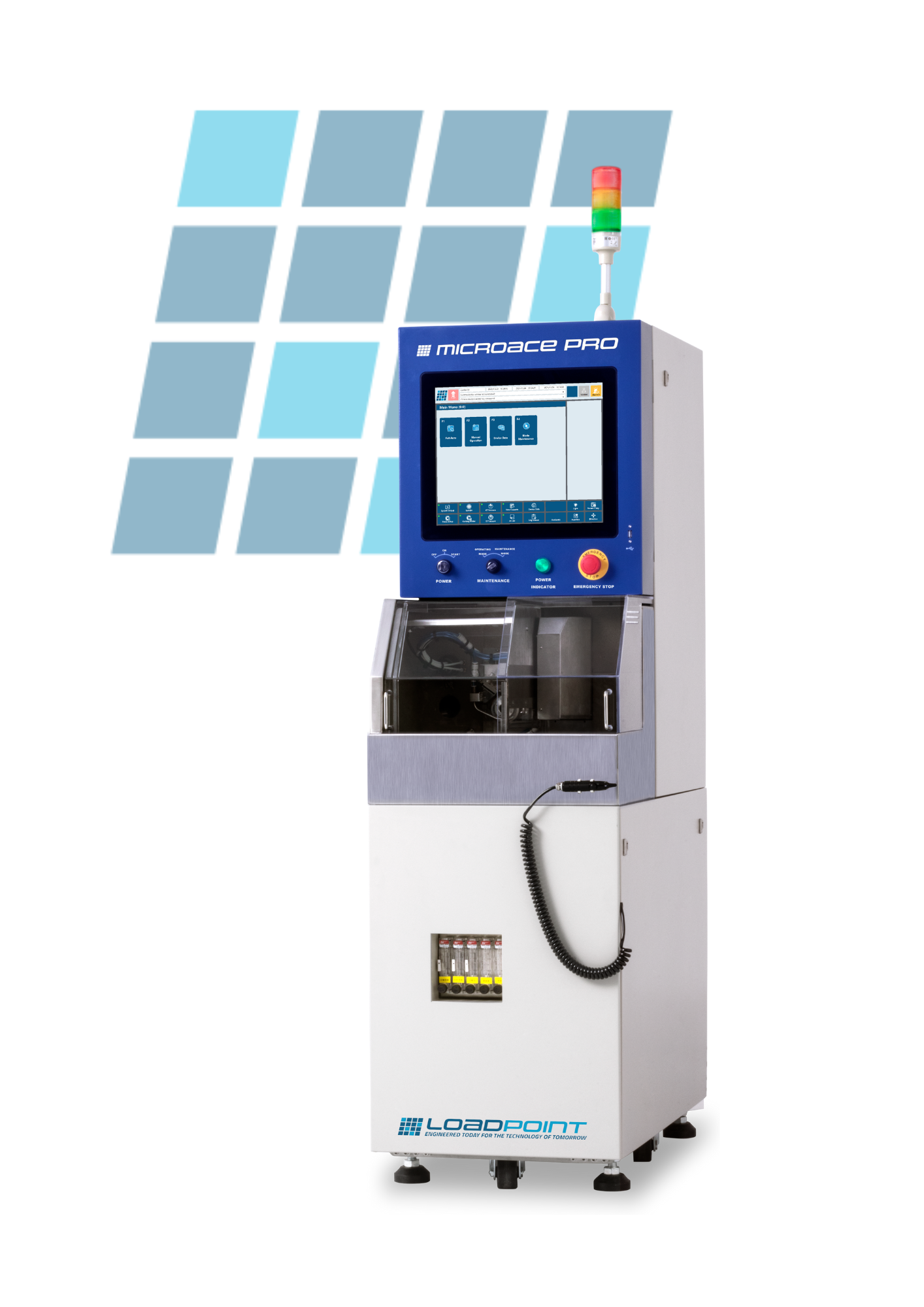

Microace PRO 🆕

The MicroAce Pro is a newly developed 6” semi-automatic dicing saw, equipped with a 2.2kW spindle as standard, while other spindle configurations are also available to suit a variety of applications including thick substrate cutting. The MicroAce Pro is suitable for a wide range of applications, not limited to silicon wafer dicing. It offers a high level of configurability to ensure optimal performance for your specific application.

This machine has a very small footprint. It features an auto-alignment function, auto kerf check function, self-adjustment function, and fragment shape recognition function.

The performance of the MicroAce Pro is underpinned by a new Loadpoint NanoControl control system, which is equipped with a user-friendly 17" LCD touch screen and operated through an intuitive new user interface.

| Max. Work Capacity (X, Y, Z) | Ø 150 mm |

| Blade Capacity (Diameter) | 49mm – 60mm, Custom Options Available |

| Chuck-type | Ceramic or metal vacuum |

| Spindle Power / Torque | 2.2 kW @ 60,000 rpm (0.42N.m. torque) |

| Footprint (W x D x H) | 570mm x 1165mm x 1780mm |

Dicing solutions for:

From Prototype to Production and Everything In-between

-

FROM THE LATEST WAFER DESIGNS TO CERAMIC COMPONENTS AND EVERYTHING IN BETWEEN

-

WITH THE MAXIMUM STROKE OF 30MM IN THE Z AXIS, THE MICROACE PRO HAS ALL DICING REQUIREMENTS COVERED

-

TOTAL FLEXIBILITY, TOTAL CONTROL

Operational Specification

| Control System | Loadpoint NanoControl 3.0 |

| Work Holding | Ceramic or Metal Vacuum Chuck, Mechanical Vice, Magnetic Chuck, Custom Options Available |

| Work Capacity | Ø 150 mm |

| Blade Capacity (Diameter) | 49 - 60mm Custom Options Available |

| Spindle Power | 2.2 KW @ 60,000 rpm |

| Spindle Speed | 3,000 - 60,000 rpm |

| X Axis Cutting Range | 160 mm |

| X Axis Resolution | 0.1 µm |

| X Axis Feed Rate | 0.1 - 600 mm/s |

| Y Axis Index Range | 0.001 - 162 mm |

| Y Axis Resolution | 0.1 µm |

| Y Axis Index Accuracy | ± 0.002mm / 160mm |

| Z Axis Index Range | 0.001 - 30mm |

| Z Axis Resolution | 0.1µm |

| Z Axis Index Accuracy | < ± 0.001 mm |

| Theta Axis Drive | Direct Drive Torque motor |

| Theta Axis Range | 320°(continuous) |

| Theta Axis Resolution | 1.5 arc sec |

| Camera Type | Monochromatic |

| Camera Alignment | Manual or fully automatic |

| Camera Resolution | 2 MegaPixels |

| Camera Magnification | x48 - x96 - x386 |

| Camera Illumination | Coaxial and ring (with dark field option) |

| Footprint (WDH) (height includes status light) | 570 x 1165 x 1780 mm |

Service Requirements

| Electricity | 220/240v AC single phase 10A, 50/60Hz |

| Air supply | 5 - 8 Bar (72 - 116 PSI) |

| 0.2m³/min (7 CFM) | |

| Dewpoint 5°C, Oil 0.005 PPM | |

| Water supply | |

| Blade coolant | 3 - 4 Bar (43 – 58 PSI) |

|

3 Litres/min (0.79 US gal/min) |

|

| Workpiece wash | 3 - 4 Bar (43 – 58 PSI) |

| 3 Litres/min | |

| Spindle coolant | 3 - 4 Bar (43 – 58 PSI) |

| Ambient temp | |

| 1.5 Litres/min | |

| Vacuum supply | Not required, internally generate |

| Mist extraction | Mandatory ≥ 1.8m³/min |

| Drain | 29 mm ID drain |

| Drain height < 473 mm from base of m/c | |

| Recommended Environment |

Ambient temp of 20˚C to 25˚C ± 1˚C, humidity level < 40% |

| Weight | 450KG on 4 adjustable feet (up to 10mm) |

| Floor Level | < 6mm across m/c footprint |

Pipe Sizes

| Port | Pipe Diameter |

| Cutting Wheel Blade Coolant In | 12mm (Outer Dia) |

| Wafer Wash Water In | 12mm (Outer Dia) |

| Spindle Coolant Water In | 10mm (Outer Dia) |

| Spindle Coolant Water Out | 10mm (Outer Dia) |

| Air In | 12mm (Outer Dia) |

| Vacuum Venturi Exhaust | 8mm (Inner Dia) |

| Mist Extraction Port | 50mm (Inner Dia) |

| Drain Port | 32mm (Inner Dia) |

Talk to us about your requirements

Standard Package

Loadpoint Air Bearing Spindle

- Very low vibration improves the cut quality and reduces chipping

- DC brushless drive, 1.8 kW 60,000 rev per min

- High power option 2.2 kW 60,000 rev per min

Vision and alignment system

Manual and automatic alignment modes:

- Monocular video alignment system with pattern recognition

- Pattern Recognition System (PRS)

- Automatic alignment as standard

- Automatic cutting & kerf check as standard

- Full 17” touch screen monitor for alignment, data entry and machine monitoring

- Continuous live display of X,Y,Z and theta co-ordinates

- Z autofocus set up of alignment image with offset option

Tooling

- Standard wheel carrier with 50 diameter blade capacity

- Three direction coolant delivery; main blade coolant jet, blade side wash bars and wafer flood jets

- Accelerometer based Z datum set, off-chuck height sensing system

Z height sensing

Off-chuck height sensing system ensures constant depth of cut without having to use conductive blades, providing a wider choice of blade diameters and suppliers.

Work holding

Standard packages include adaptable plain wafer vacuum chuck for use with wax and substrate mounting and tape rings. Loadpoint manufacture chucks for all tape rings and film frames, mechanical vices, and designs to customer requirements, including precision-ground ceramic inserts for improved vacuum and component support.

Materials Processed

Ceramic, FR3/FR4, GaAs, Germanium, Glass, InP, LED’s, Lithium Niobate and Tantalate, QFN, Piezo electrics, PZT, Quartz, Sapphire and Silicon amongst others.