Metrology

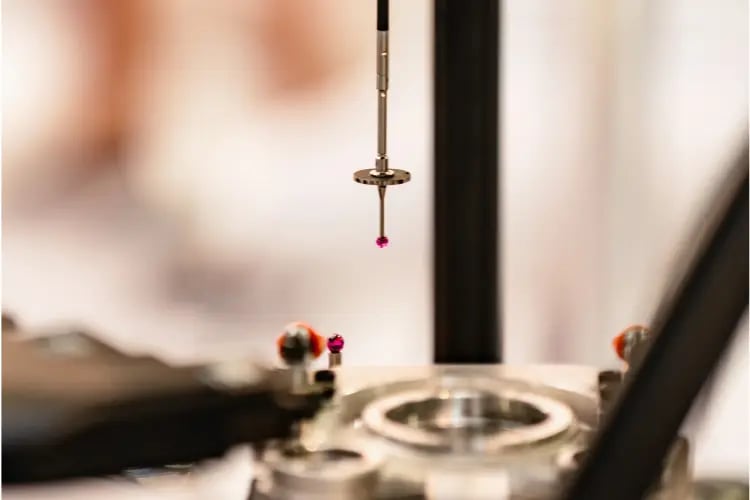

Metrology is the science of measurement. It's a field which ensures the precision, accuracy, and consistency of measurements across industries, impacting everything from the smallest manufactured components to large civil engineering projects. Metrology underpins our ability to standardise and calibrate tools, instruments, and methods, ensuring industries worldwide have a common reference for their work.

The metrology sector's primary requirements are stringent. Companies need to ensure that its equipment can consistently produce and measure cuts to incredibly tight tolerances, often at the micron level or even finer. Additionally, given the critical importance of measurement accuracy in metrology, equipment must be regularly calibrated and verified against established standards.

Your world

In the world of metrology, where measurement accuracy is the cornerstone of our operations, we know you demand unparalleled precision and reliability from your partners.

You are looking for more than just state-of-the-art dicing and processing solutions. We know you seek a deep understanding of the complexity intrinsic to metrological applications.

The components you work with ensure measurement fidelity. Even the slightest deviation can have damaging implications.

As metrological techniques evolve and the demand for micro-level precision grows, it's imperative that your partners remain agile, adapting their technologies to suit the ever more exacting needs of the sector.

Typical issues

Ultra-precise component creation

One of the biggest challenges in the metrology sector is the need for ultra-precision. Given that metrological tools and instruments are used to measure with high accuracy, any component imperfection or inconsistency can directly impact the reliability of measurements.

This challenge is compounded when dealing with micro-components or those that require complex geometry, as traditional dicing methods may not always deliver the required precision or might introduce unwanted aberration.

Staying ahead of the game

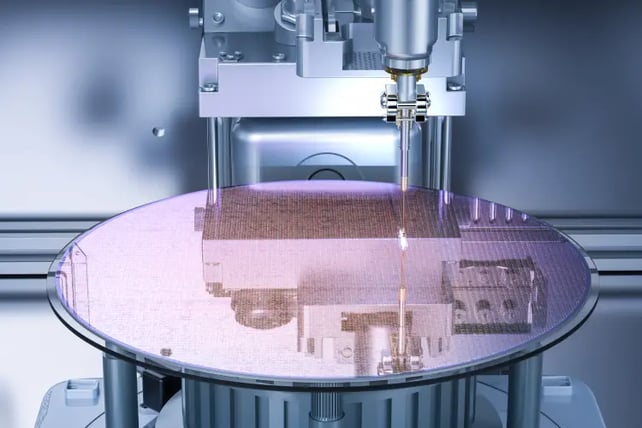

The metrology industry is consistently evolving, with new techniques and technologies emerging at a rapid pace. Keeping abreast of these advancements and ensuring components and tools align with the latest metrological methods can be difficult.

This dynamic nature demands agility in dicing and processing solutions, ensuring that components are always in sync with the latest in metrological innovation.

Loadpoint Insights

Loadpoint Debuts at LASER World of PHOTONICS CHINA!

Loadpoint Shines at the 50th Annual EFCLIN Congress and Exhibition

Quantity AND Quality

As metrology expands across industries and sectors, there's a growing demand for instruments and tools that can cater to a broad spectrum of needs. This means scalability in production, but often, scaling up can compromise on quality.

The challenge lies in maintaining accuracy even as production volumes grow, ensuring that every component, irrespective of the batch size, meets the exacting standards of the sector.

Why work with Loadpoint?

In the precision-centric world of metrology, Loadpoint emerges as both reliable and innovative. Beyond just craftsmanship, our agility in adapting to rapid technological shifts.

Loadpoint's agility in adapting to rapid technological shifts ensures that metrological tools always align with cutting-edge methods.

Our scalable solutions strike a perfect balance between volume and precision, enabling metrology companies to expand operations without compromising accuracy they live by.

In partnering with Loadpoint, you are equipped with the tools and expertise to navigate the unique challenges, the sector produces.

Contact us

When it comes to Metrology, Loadpoint has the measure of things.

Contact our experts now.